ABOUT US

N-J® Valve provides reliable automation products and services to our customers, meanwhile optimizes product functions.

A stable platform for automation business development, which consists of a comprehensive product portfolio, advanced technology and network service provided by N-J VALVE.

Automation Product Solutions

Introduce world-advanced technology for valve design and manufacture, continuously adopt new materials, new processes, and new technologies to improve the accuracy and quality of product

components and ensure well performance of the product, making N-J VALVE products more competitive and meeting the requirements of various working conditions.The company is constantly researching the formula and processing technology of sealing materials, and able to provide pure PTFE and reinforced polytetrafluoroethylene sealing materials. According to user requirements, various polymer sealing materials imported from the United States are also provided. These materials are suitable for special purposes such as higher temperature, pressure difference and radiation resistance.

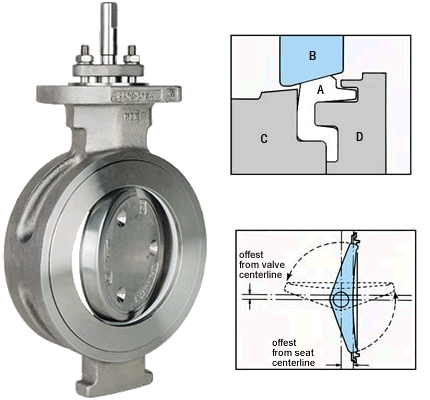

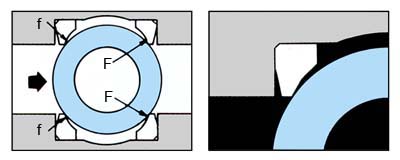

Read more...Double eccentric design - The eccentric butterfly plate and the offset shaft ensure that when the valve is opened, the sealing surface of the butterfly plate quickly detaches from the sealing surface of the valve seat, so that there's only short contact, which prolongs the lifecycle of the valve and also maintains the tightness of the entire periphery of the butterfly plate.

The product can be used in harsh natural environments. It can withstand the effects of combined loads such as earthquakes, ground loads, pipeline stresses, etc. in the wild environment.

From Market Development, Order Placement to Product Delivery

The company adopts multiple information technology platforms, including ERP, CRM, MES, CAD/CAM, OA, etc.

Read morePerformance Characteristics of Products

We constantly improve the sealing performance of the valve, when there exists a large difference range of pressure and temperature. Maintaining low operating torque and long lifecycle to reduce the leakage of valve stem packing is also our tireless goal.

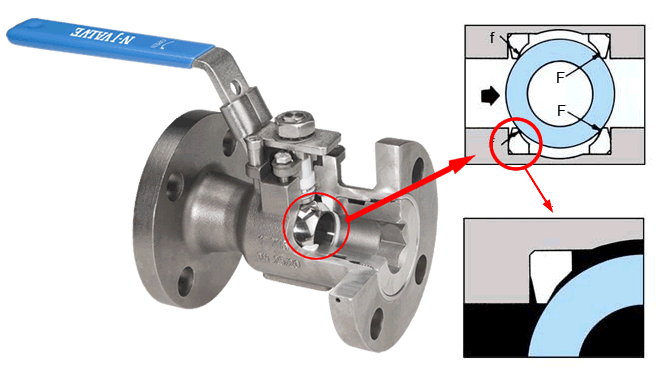

Floating ball valves

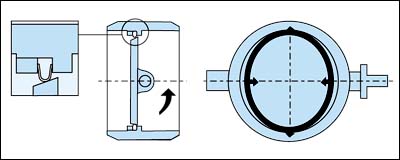

The full channel and low flow resistance characteristics of the ball valve have been widely used in oil and gas pipelines, and are quickly accepted by the nuclear industry, aerospace industry and other high-tech fields, used to transport dangerous media and ultra-low temperature liquids. After that, the new areas of high-parameter ball valves were constantly expanded for: large diameter, high pressure, low temperature, ultra-low temperature, high temperature, high vacuum and solid particle transportation.

Read more...Pipeline Ball Valves

Pipeline Ball Valves - A dedicated ball valve designed according to the special technical requirements of long-distance pipelines. It adopts a fixed ball, a floating seat design, a three-section forged steel valve body, and a bolt connection structure, which is convenient for online maintenance. It is an ideal valve for medium control of oil (crude oil, refined oil), natural gas and other transportation pipelines.

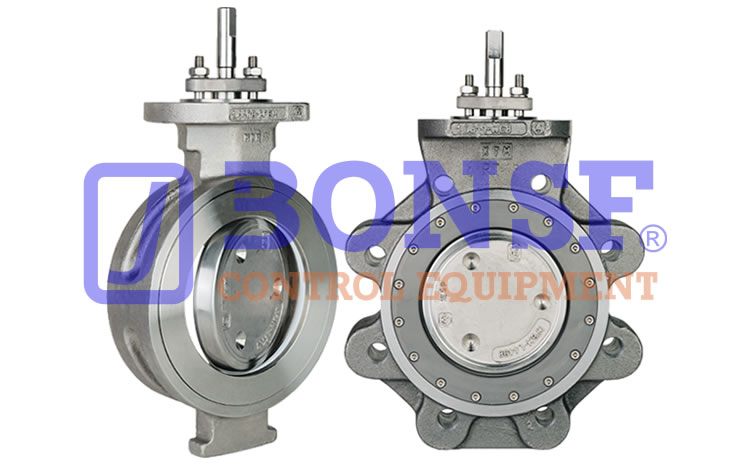

Read more...High Performance Eccentric Butterfly Valves

According to the sealing principle and sealing technology of the ball valve, there are wafer and earring type for the innovative single-seat high-performance butterfly valve.

The design of eccentric butterfly plate and the offset shaft ensures that when the valve is opened, the sealing surface of the butterfly plate quickly detaches from the sealing surface of the valve seat, so that there's only short contact, which prolongs the lifecycle of the valve.

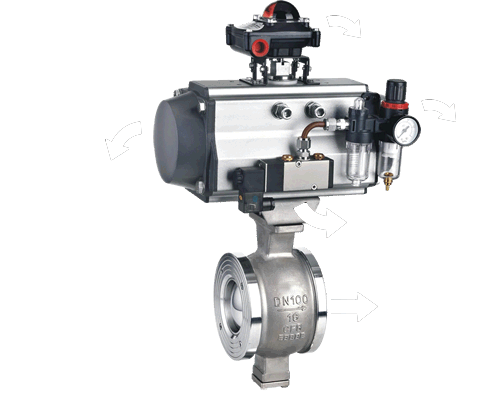

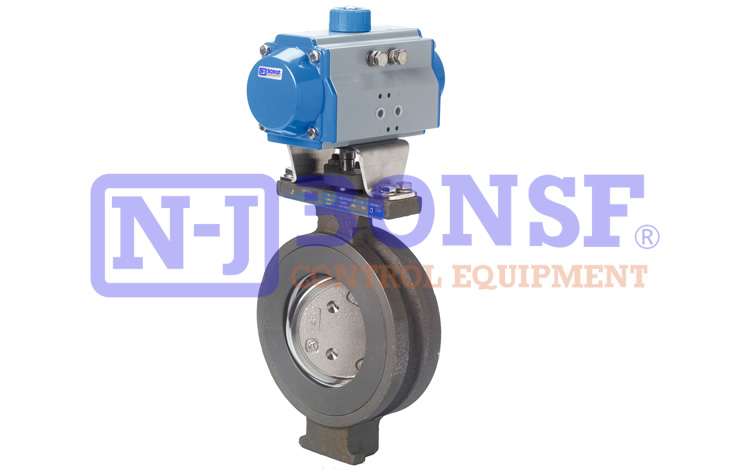

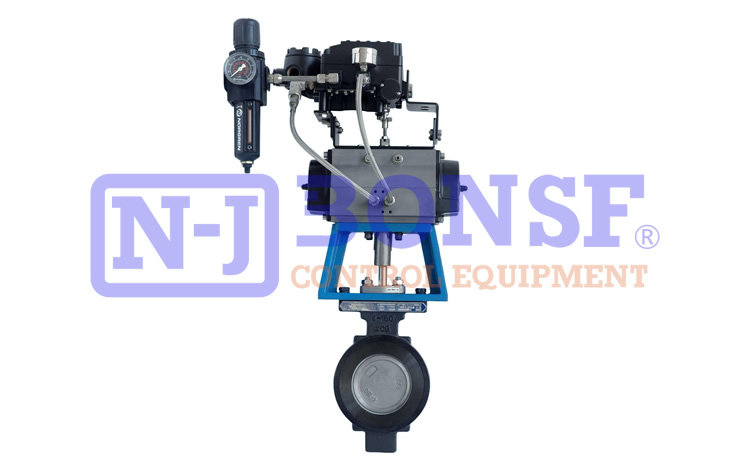

Executing Agency and Accessories

The matching design of valves, driving devices and accessories ensures highly coordination and consistency in the overall operation. The drive unit and accessories are assembled and shipped out of the factory. Warranty included.

In order to meet the needs of different working conditions, we provide pneumatic, electric, hydraulic, gas-liquid linkage and other operation modes, as well as control accessories for explosion-proof and non-explosion-proof areas.

Popular Products

You may be interested in the following products

800 Series High-Pe...

These high performance butterfly valves provide long lasting tight shut-off or control capability...

VPVL Series Pneuma...

VPVL Series actuators are double-acting or spring return rack and pinion actuators.These double–opposed…

800 Series Pneumat...

These high performance butterfly valves provide long lasting tight shut-off or control capability...

600 Series Model A...

This series of full port flanged ball valves has the same design features as the Series 6000 product...

G Series Trunnion ...

The G series is a trunnion mounted polymer-seated ball valve, which provides excellent tightness...

800 Series Control...

These high performance butterfly valves provide long lasting tight shut-off or control capability...

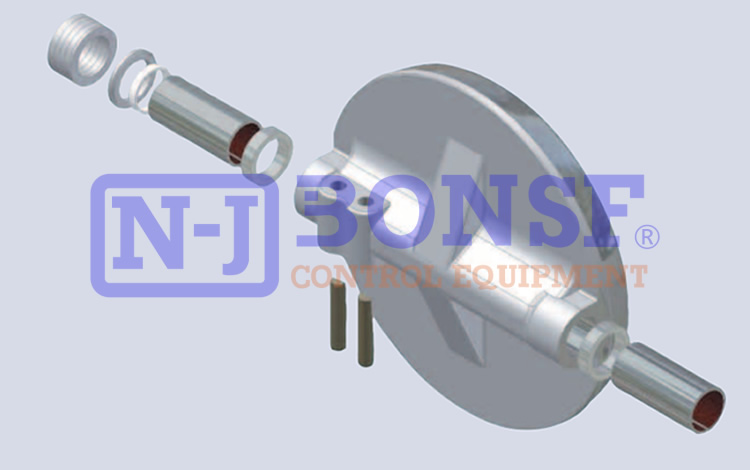

Valve spare parts ...

In the daily use and maintenance of the valve, the vulnerable parts of the valve are often damaged....

600 Series Full Po...

This series of full port flanged ball valves has the same design features as the Series 6000 product...

5000 /7000 AND 600...

These polymer-seated flanged ball valves incorporate flexible-lip seat design that provide positive shut-off ...

T4H Series single-...

T4H Series single-seat control valve can be used to control various pressure and temperature fluids The valve...