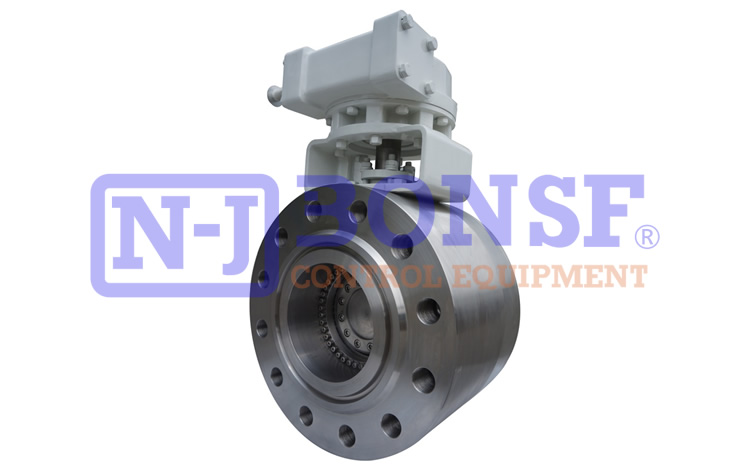

HP Series metal-seated butterfly valves

Product Description

HP series butterfly valve performance advantage is mainly reflected as follows:

Bi-directional pressure bearing:

The analysis of optimization of three eccentric parameter through self-developed design software, with the measures to improve main components’ geometric and dimension tolerance accuracy to achieve series HP butterfly valve bi-directional pressure bearing and arbitrary flow installation.

Overall metal forged valve sealing ring and seat:

The sealing ring and seat use overall metal forged crafts with all sprayed Stellite or various sealing material that’s more suitable for working conditions. After Stellite sprayed, the sealing components can be abrasion resistance, anti-erosion, longer service life with high sealing performance to achieve zero leakage.

On-site replaceable sealing components:

The sealing ring and seat can be replaced by dismantled from the valve with no need to disassemble the whole valve. This achieves rapid on-site maintenance and makes the valve’s service life parallel to that of the pipeline so that directly reduce production and equipment maintenance costs.

HP series butterfly valve is suitable for various complex medium and working conditions:

can endure high pressure and high temperature up to 850℃, low temperature to -196℃. And it’s safety under the condition of various pressure up to 2500LB and bi-directional pressure bearing up to 600LB.